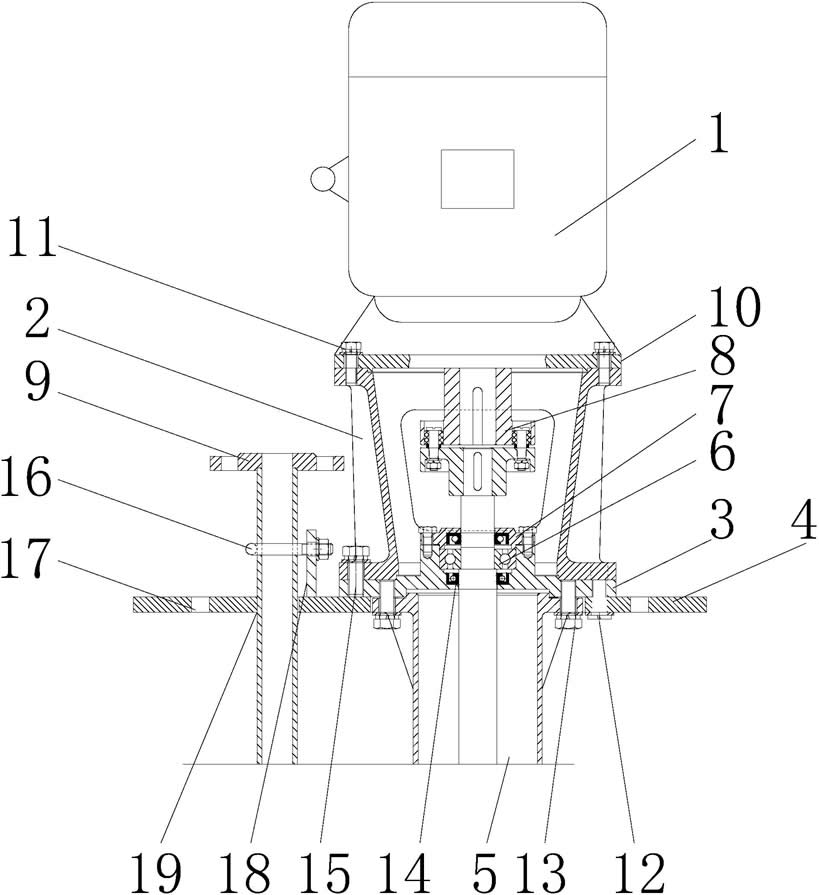

A suspension type semi submersible vertical turbine pump shock absorber base, comprising a motor and a motor seat. The bottom of the motor is fixedly connected to the motor seat, and the bottom of the motor seat is fixedly connected to a bearing seat. The bottom of the bearing seat is fixedly connected to a bottom plate, and the bottom of the bearing seat is fixedly connected to a suspension type semi submersible vertical turbine pump. The bottom of the suspension type semi submersible vertical turbine pump penetrates the bottom plate and extends to the bottom of the bottom plate. The top of the bearing seat is fixedly connected to a bearing inside the motor seat, and the top of the bearing is fixedly connected to a bearing cover. The bearing cover is fixedly connected to the output end of the motor through a connector. The top of the bottom plate is fixedly connected to a water outlet pipe located on the left side of the motor seat. The bottom of the base plate runs through and extends to the bottom of the base plate, A motor flange is filled between the motor and the motor base. This technical method solves the problem of excessive vibration and inability to meet the needs of traditional suspended semi submersible vertical turbine pumps through the combination of motors, base plates, suspended semi submersible vertical turbine pumps, and outlet pipes.

Technical requirements: 1. Suspension type semi submersible vertical turbine pump shock-absorbing base, comprising a motor (1) and a motor seat (2), characterized in that: the bottom of the motor (1) is fixedly connected to the motor seat (2), the bottom of the motor seat (2) is fixedly connected to the bearing seat (3), the bottom of the bearing seat (3) is fixedly connected to the bottom plate (4), the bottom of the bearing seat (3) is fixedly connected to the suspension type semi submersible vertical turbine pump (5), the bottom of the suspension type semi submersible vertical turbine pump (5) penetrates the bottom plate (4) and extends to the bottom of the bottom plate (4), and the top of the bearing seat (3) is located at the top of the motor seat (2) The internal fixed connection of the motor (1) is equipped with a bearing (6), and the top of the bearing (6) is fixedly connected with a bearing cover (7). The bearing cover (7) is fixedly connected to the output end of the motor (1) through a connector (8). The top of the bottom plate (4) and located on the left side of the motor seat (2) are fixedly connected with an outlet pipe (9), The bottom of the water outlet pipe (9) runs through the bottom plate (4) and extends to the bottom of the bottom plate (4), and a motor flange (10) is filled between the motor (1) and the motor seat (2).

Vertical PWDDFL Multi-suction Sewage Sump Pump

VS6 Vertically Suspended Radial Canned Turbine pump

Vertical turbine Industrial Can-Type Pumps

Semi-submersible Vertical Industrial Turbine Pumps

Semi-submersible Canned Vertical Turbine pump

Short-Set Vertical Turbine pumps

Vertical Cryogenic Process Canned vertical turbine pump

Vertical Canned Process Semi-submersible turbine pump

Canned Vertical Turbine Generators Pump

Vertical long shaft turbine pumps

Semi-submersible Mixed-Flow Vertical Turbine Pumps

Vertical Semi-submersible chemical sump pump

TEL:073184800558 073184810558

Cell Phone:008618507312158 008613974960765

E-mail:sale@ljpump.net

Address:Xiangyin Industrial Park, Jinlong Town, Xiangyin County, Hunan Province, China